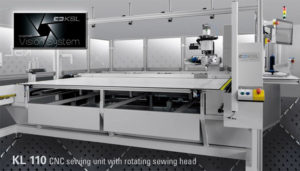

At Texprocess fair, in US PFAFF Industriesysteme und Maschinen GmbH (KSL-Site Lorsch) showed the new KL 110 with Vision System. The machine is a CNC sewing unit with rotating sewing head (sewing area 2,500 x 1,000 mm) for servo-motorically controlled sewing of free programmable decorative seams. Equipped with Vision System, the sewing unit is predestinated for top-stitching partially perforated materials made of leather and PVC in the automotive interior sector.

The intelligent Vision System (equipped with up to 4 cameras) compensates tolerances that arise in the seam contour as a result of material shrinkage and tolerances when punching the perforation, among other things. Specifically, the Vision System compares the image of a master part with the image of a part clamped in the sewing template. The complete seam design is then automatically corrected in the sewing programme based on the individual measurement points. Thus Vision System makes it possible to sew between the perforations with mm precision and to compensate the resulting tolerances. It is possible to compensate tolerances of up to 4 mm in the X and Y axis. The machine achieves a maximum speed of 2,800 s.p.m. Electromagnetic thread trimmer for upper and lower thread and upper thread monitor is standard equipment of the machine. The thread tension may be regulated via touch-panel. The maximum stitch length is 12 mm.