TENCEL® branded lyocellfibres are demonstrating their worth in the hotel business in bed linens. TENCEL® fibres have no problem meeting the highest standards in bed linens. Years of product developments with international partners in industrial linens and bed linen manufacturers have led to success. The results were presented at Heimtextil 2017 in Frankfurt for the first time.

Bed linens of TENCEL® fibres are not only for home use

“Following intensive effort on our part, we have developed excellent bed linens for the hotel trade. Now business travelers or wellness guests can also experience TENCEL® fibres bed linens,” Susanne Jary, Home & Interior Director at Lenzing, comments. “It was no easy task to get TENCEL® fibres fit for industrial laundries. After years of cooperation with partners in industry, technical recommendations have been developed for cleaning hotel bed linens in industrial laundries,” Jary explains.

International partners are ecstatic

“The properties of the TENCEL® fibres, such as high dry and wet strengths, make it possible to use the fibres in industrial laundries. As a result of the softness and high moisture absorption, it is possible to process the TENCEL® fibres bed linens faster and saving more CO2 than bed linens of other materials,” TextilpflegeLeitgeb, a rental service provider from Austria, comments. The German rental service providers “Dibella” are well known for the responsible way they handle hotel textiles and constantly search for new eco-compatible materials. “With the TENCEL® fibres we have found a material that has a lower eco footprint and a high textile resistance, which is again extremely important for the hotel industry,” Dibella explains. “After three years of development work, we have found the right fibre blend that meets our demands and the demands of our customers,” Dibella continues. The first bed linen suitable for leasing is made of 60 per cent TENCEL® fibres and 40 per cent cotton and has surpassed Dibella’s expectations.

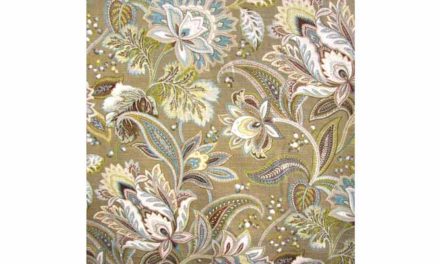

The American manufacturer, Valley Forge Fabrics, works with internationally renowned hotel chains and specialises in TENCEL® fibres in the segment of furniture fabrics and bed linens. “We are convinced that we have changed the way that our customers see textiles in the hotel sector. Ecological compatibility and health aspects now have an influence on their purchase decisions. For us it is important to tell this unique TENCEL® fibres story,” Valley Forge Fabrics explain in one statement.

The Austrian company HEFEL Textil is a pioneer in the field of the production of TENCEL® fibres bed linens. HEFEL Textil started to use the TENCEL® fibres in their bed linens as early as 1998. “Many of our customers are exclusive hotels thus it was natural to use TENCEL ® fibres in the hotel sector as well. The bed linens are characterized by the unique combination of skin-friendly and easy-care properties,” Hefel comments. A pilot project convinced HEFEL Textil and confirmed TENCEL® fibres as a fixed feature in the hotel industry. “Mostly, however, the hotel guests will enjoy bed linens of TENCEL ® fibres,” HEFEL Textil is sure.

The future in the hotel industry

Lenzing is continuing to expand applications for TENCEL® fibres in the hotel business. “First and foremost, it is a stable business and one in which we can reach end consumers directly in partnership with the hotels,” Jary explains. “Guests can experience TENCEL® fibres directly at hotels and can then acquire the feel-good fibre for their use at home. The possibilities in this sector are interesting both for the hotel business as well as for final consumer marketing,” Jary is convinced.