The United Nations in the year 2015 came up with 17 Sustainable Development Goals as a standard which each country had to achieve by the year 2030 in order to bring about their overall development. Amongst the various important topics which were so discussed, reduction in actions for Climate Change, access to clean water and Sanitation, and responsible consumption and production to reduce the impact on environment are the ones which are stressed upon tremendously, where the global corporate community need to take a lead in order to achieve the Sustainable Development.

Experimentation with fashion by the consumers and rapid growth of fast fashion has correspondingly lead to thousands of tons of fabrics, clothes, & other materials finding their way to the dumpster every day. The textile industry is discredited for being one of the most polluting industry globally and the consumers of textile goods are conscious and increasingly concerned about the sustainability related aspects of the products that they chose to wear.

Birla Cellulose, the Pulp and Fibre Business of the Aditya Birla Group in cooperation with its value chain partners is fully engaged in the implementation of actions that are needed to achieve the Sustainable Development Goals. Birla Cellulose has inculcated this ideology of sustainability at the core of our business strategy focusing on actions that create positive impact on the people and the planet. In furtherance of the aforementioned cause, the company in the year 2019 launched LIVAEco, a soft, breathable, and fluid fabric which is manufactured with an objective of delivering a product with unmatched sustainability such as sustainable forestry, manufactured with benchmark resource efficiency using closed loop production systems, lower water footprint, lower GHG emissions and complete traceability of the value chain.

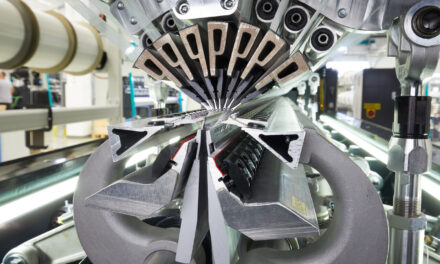

LIVAEco is made from fully renewable natural raw materials sourced from sustainable forestry certified by the Forest Stewardship Council, a premier NGO which works towards the conservation of trees. The production of the said fibre is done using highly efficient closed loop production process that helps recover and reuse chemicals and water used in the process. LIVAEco saves up to 900 liters of water and reduces 300g of CO2 per garment. In addition, the production process has a mechanism which ensures traceability of the product, which enables the consumer to know where the fibre was produced. Viscose being fully biodegradable finds the perfect answer to the problem of ending up as a waste in landfills or contaminate soil and aquatic bodies.

The Aditya Birla Group, realizes the responsibility of the textile industry in satisfying the needs of the customers related to products functional attributes and also address the concerns on being environment friendly at the same time. It has been forever a challenging task for companies to fuse sustainable solutions in a fabric preferred by the customer and we have finally been able to find a solution to the same. The launch of LIVAEco has been accepted gracefully in India as it promoted the concerns of the environmentally-conscious people. The next step was to take LIVAeco in markets outside of India.

Intertextile/ Yarn Expo offered the best platform to launch LIVAeco in China. China by virtue of being the largest producer and exporter of textile into the world, has to play a leading role in improving the environmental footprint and enhance its long term sustainability.

“Chinese Textile industry, being the global manufacturing hub, has come into serious spotlight for the impact created by it on the environment. Birla Cellulose has prioritized the launch of LIVAEco in China in collaboration with our value chain partners to support this cause by starting the manufacturing of this product at its plant at Birla Jingwei fibre Company Limited, in order to create a greater and broader positive impact on the environment,” said Dilip Gaur – Managing Director Grasim Industries Ltd.