Hohenstein, a testing services provider and research partner, has completed development of its new method for analysing microfibre shedding from textiles. Using dynamic image analysis, the method quantifies shedding behaviour and reveals previously unattainable data with practical implications for material development throughout the supply chain. With this level of detail, researchers can now quantify in more detail which types of fibre and material constructions contribute most to microfibre release, leading to informed decisions in development of more sustainable textiles that shed less. The new method is the result of four years of research at Hohenstein, published in an article by lead researcher Jasmin Haap. The research team developed, refined and validated an analytical method that goes beyond current approaches of measuring the shedded mass to quantify fibre count, length, diameter and shape.

Hohenstein, a testing services provider and research partner, has completed development of its new method for analysing microfibre shedding from textiles. Using dynamic image analysis, the method quantifies shedding behaviour and reveals previously unattainable data with practical implications for material development throughout the supply chain. With this level of detail, researchers can now quantify in more detail which types of fibre and material constructions contribute most to microfibre release, leading to informed decisions in development of more sustainable textiles that shed less. The new method is the result of four years of research at Hohenstein, published in an article by lead researcher Jasmin Haap. The research team developed, refined and validated an analytical method that goes beyond current approaches of measuring the shedded mass to quantify fibre count, length, diameter and shape.

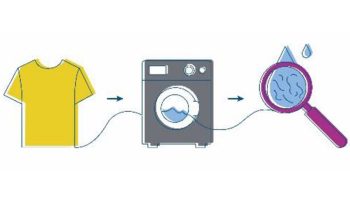

Further analysis can reveal the distribution of these attributes and even generate separate results for cellulosic fibres (eg cotton) and non-cellulosic fibres (eg polyester). This analysis is currently available exclusively through Hohenstein. Synthetic microfibres are tiny pieces of plastic released into water during mechanical stress, particularly washing. Wastewater containing microfibres eventually flows through sewage into larger bodies of water. Along the way, synthetic microfibers attract harmful substances and pollutants from the environment, harming sea life and entering the food chains of larger fish and humans.

Dynamic image analysis of wastewater is non-destructive, allowing additional tests, such as filtration, to be performed for further analysis. Filtration, the most common method to date, involves filtering the wastewater from textile laundering, then weighing the remaining particles. In November 2019, Hohenstein joined the Microfibre Consortium as a contributing research member.

Microfibres are tiny pieces of plastics released in the water during mechanical stress, particularly washing. Wastewater eventually flows into sewage and larger bodies of water, remaining indefinitely or entering the food chain. With over 1,000 employees in more than 40 branches, offices and laboratories worldwide, Hohenstein is a founding member and leading provider of the Oeko-Tex portfolio of services and is certified by the US Consumer Products Safety Commission (CPSC ID #1058) as a third-party, independent laboratory for CPSIA compliance verification.