The sixth edition of ITMA ASIA + CITME has received extremely strong support from both domestic and international textile machinery manufacturers. The exhibition is expected to feature some 1,700 local and international textile machinery makers from 28 economies who will showcase the latest machinery, as well as products that boost automation and energy-saving features. The sixth combined exhibition is gearing up for another huge showcase in Shanghai, China. It is expected to attract a trade visitorship of around 100,000 from around the world.

Chinese manufacturers take the largest area, followed by Germany, Italy, Japan and Switzerland. Sector-wise, spinning machinery forms the largest sector. This is followed by finishing and dyeing, knitting, weaving and nonwovens. The enthusiastic response for the exhibition is the result of China’s ongoing strategic push for innovation to enhance the global competitiveness of Chinese textile and other industry sectors under the government’s 13th Five-Year Plan period (2016 – 2020).

“We are looking forward to welcoming large numbers of visitors from both inside and outside of China to the combined show, and we would like to encourage our visitors to plan their trip early and purchase their badge online now to beat the onsite queues. Registering ahead of time on the show website provides visitors with useful information for preparing their trip and finding out the details on the exhibitors,” said Fritz P Mayer, President of CEMATEX.

Added Wang Shutian, President of China Textile Machinery Association (CTMA), “Interest in the combined show remains extremely strong, especially from Chinese textile machinery manufacturers. As China’s textile industry continues its transformation, the demand for advanced machinery and technology is on the rise.”

Additional space booked to meet demand

Due to an overwhelming response, the joint owners of the ITMA ASIA + CITME 2018 exhibition have now booked additional space at the North Hall (NH) at National Exhibition and Convention Centre (NECC). With the additional space, the sector allocation plan has been revised to accommodate more exhibitors.

According to Wang Shutian, “The strong demand for space attests to the effectiveness and popularity of the combined show. We had a long waiting list for space by the deadline for applications. Therefore, we made the decision to book the additional space available in the venue.”

In the next few pages we are highlighting some of the latest weaving technologies to be displayed during the show…

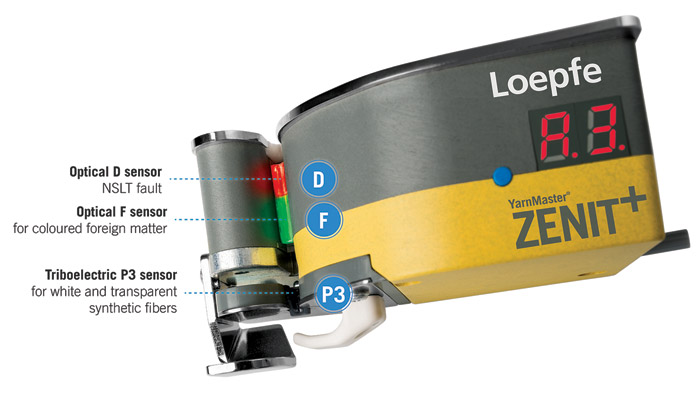

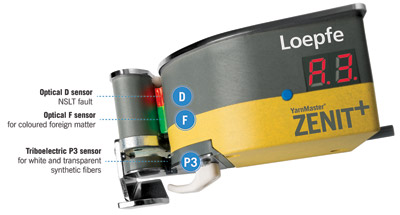

Loepfe quality control solutions on show

Loepfe, a manufacturer of sensors and monitoring equipment for yarn spinning and fabric weaving processes, will present its portfolio of quality control solutions for the textiles industry. The company’s presentation will include the well-known YarnMasterZenit+ for winding and the WeftMaster Falcon-i for quality control of high-tech materials. Various innovative solutions in different areas of yarn quality control will be shown. New measuring results of the YarnMasterZenit+ OffColor feature collected in cooperation with a customer will be available. The case study shows results in detection of shade variations in polyester.

Loepfe, a manufacturer of sensors and monitoring equipment for yarn spinning and fabric weaving processes, will present its portfolio of quality control solutions for the textiles industry. The company’s presentation will include the well-known YarnMasterZenit+ for winding and the WeftMaster Falcon-i for quality control of high-tech materials. Various innovative solutions in different areas of yarn quality control will be shown. New measuring results of the YarnMasterZenit+ OffColor feature collected in cooperation with a customer will be available. The case study shows results in detection of shade variations in polyester.

The increasingly popular yarn defect sensor WeftMaster Falconi will also be displayed. After the growing demand noticed from North America, Loepfe says it sees a similar growth in the Asian market for reliable yarn quality control of latest high-tech materials such as carbon fibres, monofilaments, multi-filaments as well as spun yarns in all material compositions. The optical yarn defect sensor removes smallest knots, fluff, filamentation, thick places and capillary breaks before being interwoven into the fabric. The sensor is being used more and more for safety-critical applications such as fabrics for airbags, tire cords, filtration materials, architectural fabrics and sailcloth where quality requirements are very high.

The Laboratory Solutions corner will also provide information. Loepfe works systematically on its laboratory test instruments. The focus during the ITMA Asia will be on the Yarnmap, which is designed to provide an increase in yarn testing efficiency with regard to time, space, maintenance and operator attendance. All kinds of short and long staple yarns are tested fully automatically while, at the same time, preparation products of the spinning mill can be tested on a second measuring sensor.

Weaving preparation and high-speed shed formation solutions by Stäubli

Stäubli Textile will be presenting its machinery range and latest solutions at two inviting booths. At Booth E01 in Hall 3, weavers will learn about innovations in weaving preparation and see high-speed shed formation solutions for all sorts of woven applications in action. Carpet weavers will see brand new pattern samples that impressively demonstrate Stäubli’s innovative binding technologies. At Booth D14 in Hall 4, knitters are invited to meet with Stäubli knitting specialists and observe the latest automation device in action – it drastically shortens the sock knitting process. ITMA Asia is an ideal opportunity to find out all about Stäubli’s comprehensive product range, which is perfectly suited to the needs of Asian mills.

Stäubli Textile will be presenting its machinery range and latest solutions at two inviting booths. At Booth E01 in Hall 3, weavers will learn about innovations in weaving preparation and see high-speed shed formation solutions for all sorts of woven applications in action. Carpet weavers will see brand new pattern samples that impressively demonstrate Stäubli’s innovative binding technologies. At Booth D14 in Hall 4, knitters are invited to meet with Stäubli knitting specialists and observe the latest automation device in action – it drastically shortens the sock knitting process. ITMA Asia is an ideal opportunity to find out all about Stäubli’s comprehensive product range, which is perfectly suited to the needs of Asian mills.

Automation in weaving preparation

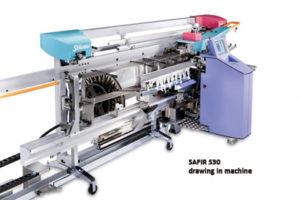

With its SAFIR automatic drawing-in machines, Stäubli has made a name for itself as an advanced solution provider for reliable automation in weaving preparation for the widest range of applications. Visitors to ITMA Asia will now see a further development: The SAFIR S30 set up especially for handling filament yarns. Featuring a new 16 frame/rod capacity, this set-up is ideal for high-density warps with fine filament yarns. The SAFIR product range features state-ofthe- art AWC (active warp control) technologies such as doubleend detection, colour repeat, and S/Z-yarn management. These technologies are the result of continuous research and development driven by Stäubli’s values such as the vision to provide innovations that deliver further advantages to customers. This spirit of innovation has now led Stäubli once again to go one step further in the warp preparation process: As a world premiere at ITMA Asia, Stäubli will unveil the new BEAMPRO yarn repeat reading-in machine, an automation aid at the sizing machine for sizing coloured warp sheets. Visitors can learn more about this weaving preparation solution at the show.

With its SAFIR automatic drawing-in machines, Stäubli has made a name for itself as an advanced solution provider for reliable automation in weaving preparation for the widest range of applications. Visitors to ITMA Asia will now see a further development: The SAFIR S30 set up especially for handling filament yarns. Featuring a new 16 frame/rod capacity, this set-up is ideal for high-density warps with fine filament yarns. The SAFIR product range features state-ofthe- art AWC (active warp control) technologies such as doubleend detection, colour repeat, and S/Z-yarn management. These technologies are the result of continuous research and development driven by Stäubli’s values such as the vision to provide innovations that deliver further advantages to customers. This spirit of innovation has now led Stäubli once again to go one step further in the warp preparation process: As a world premiere at ITMA Asia, Stäubli will unveil the new BEAMPRO yarn repeat reading-in machine, an automation aid at the sizing machine for sizing coloured warp sheets. Visitors can learn more about this weaving preparation solution at the show.

Frame weaving solutions for water-jet applications

As another novelty, Stäubli will be presenting its latest highposition rotary dobbies for water-jet applications, the S2658 and S2678 series. The S2678 will be on display in combination with the new de82/83 har¬ness motions for high mounting, featuring an ingenious design incorporating valuable features such as maintenance-free bearings. These machines can be installed in the high position on the weaving machine, supporting the production of quality patterned fabrics. In addition to the electronic rotary dobbies, Stäubli’s S1300 and S1600/S1700 series of cam motions will also be exhibited. These machines are available for high-speed weaving using every type of weft insertion system.

Jacquard weaving – Large format application on display

Visitors will see two complete Jacquard installations featuring different kinds of weft insertion. These installations are equipped with the LX and LXL Jacquard machines, designed for the production of terry and large-format clothing fabrics. Dedicated to large formats, the LXL setup is equipped with 19,584 harness cords (format of the machine exhibited is 10,240 hooks). The display will show the heavy payload capacities of this machine when weaving dense clothing fabrics. The LX setup (format of the machine exhibited is 4,096 hooks) will be shown producing terry fabric, operating 6,652 harness cords with two repeats. At the two-level booth, visitors will be able to observe the precise operation of these machines from the ground floor and from above. A DX Jacquard machine will be shown in an area also demonstrating the broad range of Stäubli harnesses.

Jacquard weaving solutions for name selvedges

Two different examples of this will be shown: The CX 172 and the UNIVALETTE electronic Jacquard machine. The latter features individual warp-thread control, opening vast possibilities for a wide variety of applications. Both machines allow weavers to apply added value to their woven fabrics.

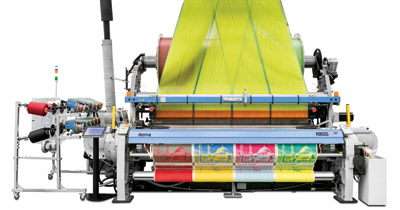

ITEMA to show high-performance weaving machinery

ITEMA is one of the world’s leading suppliers of quality, high-performance weaving machinery, and support services to the industry, based in Italy. The second generation of the ITEMA denim-dedicated rapier weaving machine, the R95002 denim will be exhibited for the first time in China for the benefit of Asia-Pacific weavers. ITMA Asia visitors will see first-hand the extraordinary advantages provided to denim weavers by the R95002 denim, ITEMA said.

ITEMA is one of the world’s leading suppliers of quality, high-performance weaving machinery, and support services to the industry, based in Italy. The second generation of the ITEMA denim-dedicated rapier weaving machine, the R95002 denim will be exhibited for the first time in China for the benefit of Asia-Pacific weavers. ITMA Asia visitors will see first-hand the extraordinary advantages provided to denim weavers by the R95002 denim, ITEMA said.

Produced and assembled in the ITEMA manufacturing plant in China, the R9000 comes at ITMA Asia in a fully revamped version by borrowing some of the latest Second Generation technological advancements implemented on the ITEMA R95002 denim. The R90002 on show at ITMA Asia – weaving a fashion apparel style – is equipped with the ITEMA FPA – Free Positive Approach weft transfer which – due to no guiding elements in the shed – ensures superior versatility. Furthermore, the R90002 will run with the Stäubli dobby 2678 providing enhanced speed and superior machine’s performances.

The R9500terry, the champion of the worldwide high-end terry weaving market comes to ITMA Asia fully loaded with its famous and unique advantages and will weave a heavy bath mat style to show its unparalleled textile versatility and superior fabric quality. ITEMA will also display the R9500 in the widest weaving width of its range, 540cm. The continuous roll-out of customised special versions tailored for technical fabrics, as well as dedicated devices for each application; make the R9500 by ITEMA the perfect machine for the manufacture of the full range of technical textiles.

On the airjet side, the show will be the stage for two ITEMA airjet machines, the A9500 weaving an apparel fabric and the A9500p weaving a bottom weight fabric. The A9500p on display during the upcoming ITMA Asia will be equipped with all the outstanding technological advancements which make this machine the most innovative airjet in the playground, including the ITEMA Double Tandem Nozzles which provide superior fabric quality and significant cost savings. Moreover, an absolute key improvement for the benefit of apparel and fashion fabrics weavers will be exhibited on the A9500 – 280cm – on show. The machine will be equipped with the new Pneumatic Tuckers for 10mm selvedges which ensure a superior fabric quality and represent a substantial added value for weavers.

Picanol to show new textile machines

Picanol, a leader in the development, production, and sales of weaving machines and technology for the textile industry, headquartered in Belgium, will display new textile machines in booth F01, hall H3. Picanol’s newest rapier, the GTMax-i 3.0, will be shown for the first time to the textile world. The GTMax-i 3.0 is building further on the success of GT-Max and GTMax-i. The combination of a redesigned gripper drive and extra reinforced sley drive as well as the integration of the future-oriented BlueBox electronic platform allow for even higher production speeds. Moreover, the look of the machine has been reworked completely, with a special focus on ergonomy and user friendliness, the company said. In total four machines of this type will be on display at the show. On the Picanol booth, a GTMax-i 3.0 will be weaving a denim fabric, another one will be weaving a zebra style curtain fabric. On the Bonas booth, a decoration fabric will be running on a GTMax-i 3.0 with jacquard, whereas on the Tongxiang booth a GTMax-i 3.0 will be weaving label.

Picanol, a leader in the development, production, and sales of weaving machines and technology for the textile industry, headquartered in Belgium, will display new textile machines in booth F01, hall H3. Picanol’s newest rapier, the GTMax-i 3.0, will be shown for the first time to the textile world. The GTMax-i 3.0 is building further on the success of GT-Max and GTMax-i. The combination of a redesigned gripper drive and extra reinforced sley drive as well as the integration of the future-oriented BlueBox electronic platform allow for even higher production speeds. Moreover, the look of the machine has been reworked completely, with a special focus on ergonomy and user friendliness, the company said. In total four machines of this type will be on display at the show. On the Picanol booth, a GTMax-i 3.0 will be weaving a denim fabric, another one will be weaving a zebra style curtain fabric. On the Bonas booth, a decoration fabric will be running on a GTMax-i 3.0 with jacquard, whereas on the Tongxiang booth a GTMax-i 3.0 will be weaving label.

Next to the all-new GTMax-i 3.0, four more machines will be present, completing the Picanol weaving machine range on display. On the Picanol booth, two OptiMax-i 190 cm weaving para-aramide and shirting are being presented. As for the airjet machines, two OMNIplus Summum will be shown, one weaving a bottom weight fabric and the other weaving sheeting. This airjet combines performance, flexibility and energy effectiveness. Waste control and style changes are simplified thanks to the Blue22 Easy Setprewinders. On the Stäubli booth, a TERRYplus Summum with jacquard will be weaving a high quality terry fabric. In total, nine Picanol machines will be on display, of which six will be on Picanol’s own booth.

Superior quality weaving machines from DORNIER

High-tech boom in China: More and more Chinese textile companies are choosing weaving machines from DORNIER in order to meet the growing demand for high quality technical fabrics for aircraft parts, filters, automotive and safety textiles. At this show, the German technology leader will exhibit the world’s most advanced weaving technology for producing high performance fabrics.

High-tech boom in China: More and more Chinese textile companies are choosing weaving machines from DORNIER in order to meet the growing demand for high quality technical fabrics for aircraft parts, filters, automotive and safety textiles. At this show, the German technology leader will exhibit the world’s most advanced weaving technology for producing high performance fabrics.

Flawless processing of high-performance fibres

DORNIER in Shanghai – for the first time ever in Asia – will exhibit its new P2 rapier weaving machine in its most powerful configuration (Type: TGP). This machine is able to bring a reed beat-up force of up to five tonne for producing wide, seamless fabrics for high density air and water filters. “The textile is exposed to exceptionally high forces specifically for wet filtration; seams are weak spots, which should be avoided if possible,” explains Wolfgang Schöffl, Head of Business Unit Weaving Machines at DORNIER.

It is no coincidence that the rising sales of weaving machines from the shores of Lake Constance are closely linked to Chinese demand for high-performance fabrics both domestically and for export: The weaving machines from DORNIER have represented the gold standard for flawless processing of highperformance fibres such as carbon, glass fibre and aramid for over 60 years.

“Made in Germany” weaving machine showroom

Besides, the P2 TGP rapier weaving machine, DORNIER is also going to exhibit other machines at the trade fair: An airjet weaving machine for manufacturing car upholstery and an airbag weaving machine will also be on display. The “Made in Germany” label is highly regarded as a hallmark of quality in China, as is borne out by an ongoing project in the town of Ürümqi. An entrepreneur has established a showroom there with a dozen or more weaving machines to show how raw textile materials are turned into fabrics for an enormous variety of applications.

Vandewiele, member firms to show innovations

The Belgium textile machinery manufacturer Vandewiele, together with its member companies Bonas, Cobble and Superba, will present a broad range of latest innovations. The highlights include a new type of Velvet Smart Innovator (VSi) for plain and jacquard velvets, latest Jaquard machine installations from the Si and Ji range as well as recent improvements in Superba’s space-dyeing technology, Vandewiele said. Vandewiele will present as a world’s first the 3 meter execution of the Velvet Smart Innovator (VSi) for plain and jacquard velvets. The main specs of the machine include parallel reed motion, reinforced cross members, single beams over the full width and up to 24 servo driven smart frames.

The Belgium textile machinery manufacturer Vandewiele, together with its member companies Bonas, Cobble and Superba, will present a broad range of latest innovations. The highlights include a new type of Velvet Smart Innovator (VSi) for plain and jacquard velvets, latest Jaquard machine installations from the Si and Ji range as well as recent improvements in Superba’s space-dyeing technology, Vandewiele said. Vandewiele will present as a world’s first the 3 meter execution of the Velvet Smart Innovator (VSi) for plain and jacquard velvets. The main specs of the machine include parallel reed motion, reinforced cross members, single beams over the full width and up to 24 servo driven smart frames.

Vandewiele Spare Parts Service will offer technical assistance to all customers for the order and delivery of original VdW parts. Technical assistance is provided with fast response and genuine parts are delivered within short delivery times. Bonas, a trendsetter in jacquard weaving, will present its most compact design, lightweight, low energy consumption and efficient techniques. The Bonas Si range is used for all applications on all possible jacquard Air jet, Rapier and Velvet looms. The other successful Jacquard range, the Ji, will also be displayed. This model is available from 1.920 up to 5.760 hooks. The Ji is manufactured in a state-of-the-art factory in Belgium as well as in a brand new plant in Nanjing. Nanjing is producing exclusively for the Chinese market.

Superba, world leader in space dyeing and heat setting machinery for carpet yarn, is well-known for space-dyeing technology, like bicolor printing, or dyeing polyester yarn, which is likely to arise great interest among the Chinese manufacturers looking for innovative end-products.